PolyBloks by PolySteel

SIMPLE.

PolyBloks are simple to use Insulated Concrete Forms that do not need reinforcing bars in a home and have steel clips that hold the forms together during concreting.

STURDY.

They uniquely use steel ties and tongue and groove joints all around their perimeters so they are virtually indestructible and far less likely to leak concrete !

METRIC.

The 1200 x 600 mm modular size of PolyBloks makes setting out in accordance with metric drawings much easier – especially floor levels and cill heights etc.

RAPID INSTALLATION

Polybloks do not need to be “unfolded” and their very large size of 0.72 square metres provides very fast wall installation and a lot less joints to leak concrete!

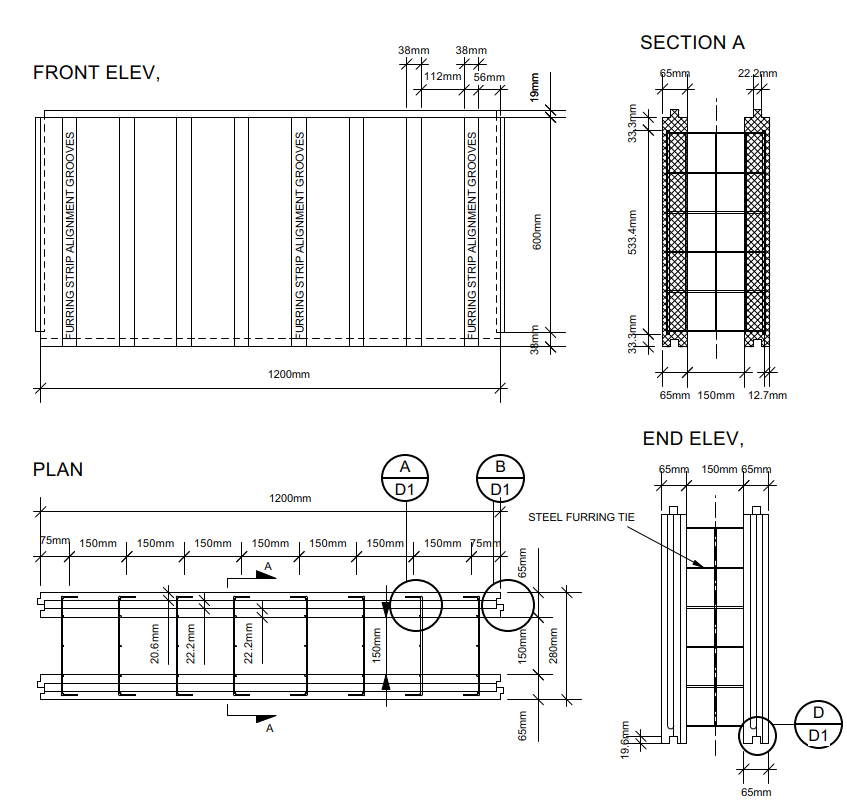

1200mm (L) x 600mm (H)

150mm concrete cores: 280mm (W)

Ideal for above ground dwellings, pool halls and garages without reinforcement.

1200mm (L) x 600mm (H)

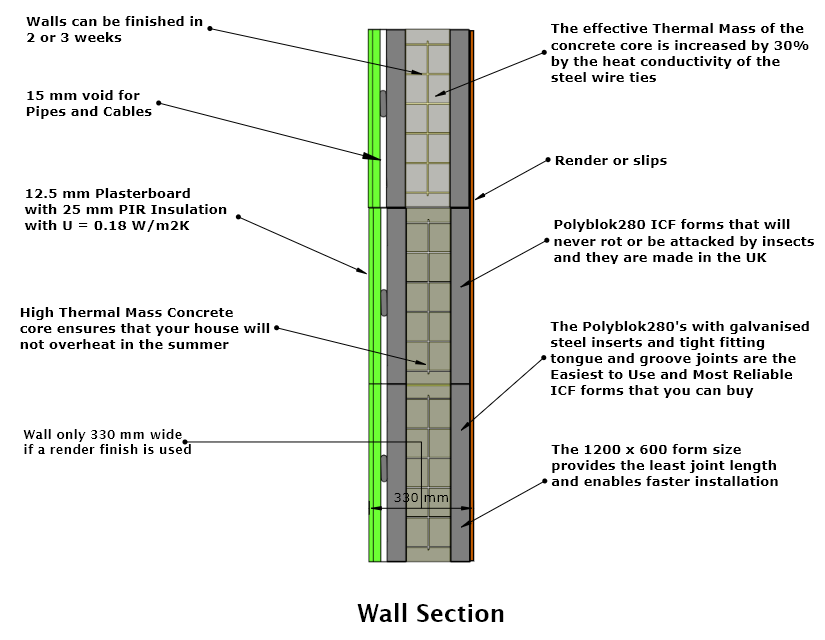

200mm concrete cores: 330mm (W)

Can be used in basements and retaining walls with appropriate steel reinforcing bars.

ICF Made Simple.

ICF PolyBlok walls provide a continuous, monolithic structure without joints or gaps. This seamless construction enhances the overall strength and integrity of the walls, making them highly resistant to external forces and impacts. Our insulated concrete blocks carry vertical and horizontal loads very effectively. They will easily withstand the loads from floors and roofs and can act as spectacular cantilevers at low cost.

ICF Forms provide excellent support for the entire building structure. They are resilient to environmental stresses such as high winds, seismic activity and temperature fluctuations. Insulated Concrete Forms are ideal for basement and retaining walls because they do not require highly skilled carpenters for construction and so provide great strength at low cost.

Metric Measurements.

ICF PolyBloks use metric measurements which makes setting out much easier. The UK and European sales of the North American ICF manufacturers is not large enough to justify making their forms in metric module sizes.

When forms are longer than 1200mm, more cutting is required to fit the doors and windows and more costly ICF waste is generated. Furthermore, when the block height is less the retained parts are shorter and less easy to stabilise for concreting.

The ICF PolyBlok module size is 1200mm x 600mm. We believe this to be the optimal size to minimise onsite cutting and offer maximum flexibility for architectural design.

Water Resistance.

All ICF walls are far more resistant to water penetration than walls built in concrete blocks. They are also more resistant than traditional concrete walls built by carpenters using shutters.

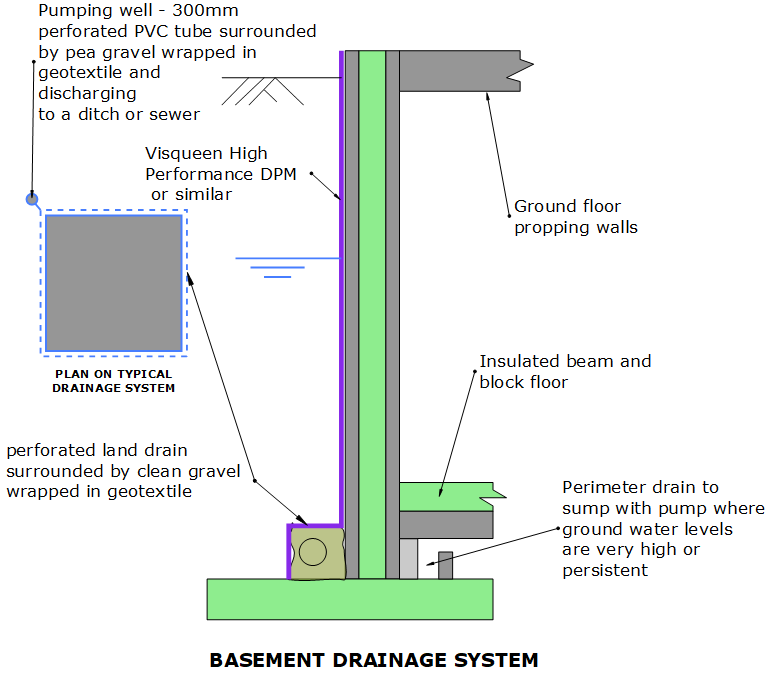

Polybloks have the advantage of the 3 dimensional wire tie system that really minimises the amount of cracking in the concrete. However, if the ground water level is a high an ICF basement can leak no matter what waterproofing or tanking is provided.

The only completely reliable system when high water levels are probable is to dewater the ground using land drainage and pumps. When necessary this can be backed up by an internal drainage system below the basement floor. During wet periods the pumps may run for long periods but this will cost far less than the damage that can be caused by water ingress.

PolySteel Construction System.

Propping

The PolySteel Installation manual provides illustrated details showing how to prop and concrete ICF blocks during construction. We use scaffolding to brace the ICF blocks during concreting and provide a completely safe concreting access platform. This avoids the need for temporary propping systems that are potentially unsafe for inexperienced users. And may not comply with the HSE rules for working platforms.

Reinforced Concrete

ICF PolyBloks are particularly suitable when reinforcement is required in the wall thanks to their rigidity. This is due to the compounding effect of tongue & groove joints (vertical/horizontal), steel ties and interlocking clips. Indeed, PolyBloks allow the concrete to be vibrated by a “poker” to ensure that adequate bonding occurs between the concrete and steel bars. This ensures structural integrity and eliminates the risk of corrosion.

Support

We provide support by telephone, email and on-line meetings throughout the construction process. The simplicity of our insulated concrete blocks and the available support ensures that your Local Builder will be able to construct your ICF home – or you can self-build it.

Design

The simplicity of the PolySteel system allows it to be used by ICF newcomers. However, it is essential that to have ICF construction details that will meet Building Regulation requirements. The Design Services we provide will ensure the Builder has all the information needed to provide a high quality insulated concrete form house.

Quality Controlled UK Manufacture.

PolySteel ICF formwork is provided with a BBA (British Board of Agrément) certificate. Ensuring all buildings incorporating our ICF concrete forms will be accepted by the NHBC (National House Building Council) and similar building insurance schemes.

BBA is the primary organisation for products used in the UK building industry. They regularly perform rigorous inspections and quality controls of all certified products. Building Inspectors may also require to see the certificate before allowing their use.

ICF PolyBloks are also certified for use in basement retaining walls. If you are planning a basement this is fundamentally important as not all ICF Building systems are certified for this type of use.

Although insulated concrete form materials are not heavy, their large volume makes them relatively costly to transport (particularly if coming from abroad). ICF PolyBloks are manufactured in Newport, Wales, which maintains low cost and limits their carbon footprint.