Building an Energy Efficient House with ICF

Insulation, air tightness and thermal mass.

Design an Energy Efficient House With ICF.

Building a modern energy efficient house requires more than just standard insulation. It requires a holistic approach to building fabric, focusing on three core pillars: Insulation, Air Tightness, and Thermal Mass. Insulated Concrete Formwork (ICF) provides the ultimate structural solution for a high-performance, energy efficient home.

The Role of Thermal Mass in an Energy Efficient House

It is a common misconception that the primary benefit of ICF is solely its insulation. While the insulation is excellent, the real secret to a truly energy efficient house is Thermal Mass.

ICF provides thermal mass in an ideal configuration. The high-density concrete core is sandwiched between two layers of insulation, allowing the walls to act as “heat batteries”:

The Polysteel Advantage: Unlike other ICF systems, each PolyBlok features x48 steel ties (3mm diameter). These conduct heat into the concrete core more efficiently, amplifying the thermal mass effect by approximately 30%.

Meeting modern U-VALUEs Economically

The current required U value of the walls in a ‘notional dwelling’ is 0.18 W/m2K, as specified in the June 1922 edition of the Building Regulations. The U value of Polyblok280 and Polyblok330 is 0.23 W/m2K. This is provided by two leaves of 65mm thickness of Neopor Insulation. This meets the notional standard below ground in basements but not above ground.

THE MOST ECONOMIC WAY TO MEET CURRENT U VALUES

Many ICF suppliers in the UK offer forms with thicker outer leaves of EPS to meet the current standard. But providing the EPS in the ICF form is expensive.

This is because:

- EPS that is formed in an EPS mould is expensive because of the cost of the factory, skilled labour and quality control

- The process of ordering, and delivering asymmetric straights and corners is complex, time consuming and mistake prone

- If insulted plasterboard is used there is no extra labour cost and the cost of high insulation value PIR is very low.

- Fixings to the firring strips are not possible because of the depth below the surface of the EPS

the best way to MEET REQUIRED u values in polyblok walls

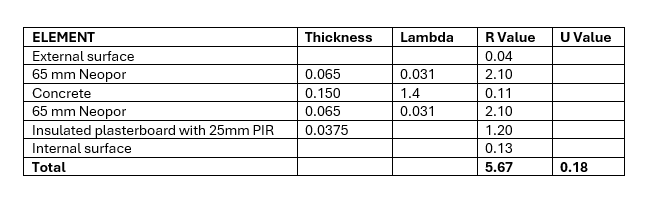

Currently the most economic way to provide an ICF wall U value of 0.18 W/m2K is to provide an internal layer of insulated plasterboard that incorporates 25mm of PIR or 38mm EPS on the inside of PolyBlok280 walls.

This minimises the area required because it is on the inside wall surface and is very economic because it does not introduce another construction operation. The U value calculation is shown in the table below.

Alternatively 30mm thick Neopor External Wall Insulation (EWI) boards can be

simply fixed to the external leaf of the Polyblok with screws and adhesive in accordance with the Polysteel installation drawings.

More About Thermal Mass.

Why Thermal Mass is so important in an energy efficient house?

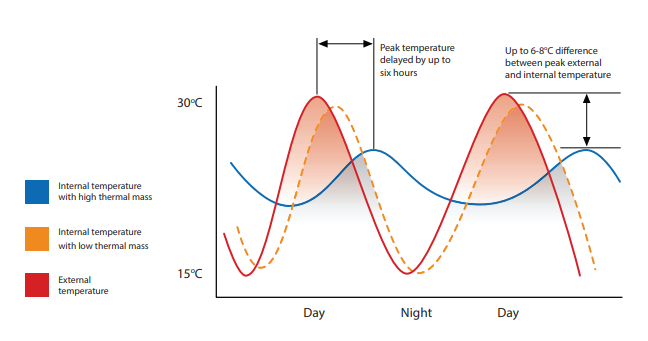

Effective thermal mass provides the means for an energy efficient house to absorb, store and release heat over time. Thermal mass helps stabilize indoor temperatures by absorbing excess heat during the day and releasing it back into the space during cooler periods. Therefore reducing the need for high powered heating systems such as gas and oil fired boilers.

How does Thermal Mass work in ICF Blocks?

In ICF construction, the concrete core between the foam panels acts as the thermal mass. In our ICF blocks, steel ties provide small bridges that reduce the R-Value by about 18%. However, they can also increase the R-value by conducting heat into the wall which increases the thermal mass effect and the R-value by about 29%. Plastic ties do not permit the transfer of heat energy into and out of the thermal mass in this way. So PolyBlok’s nickel plated steel ties actually achieve an 11% increase in R-value performance by enhancing the effective thermal mass of the concrete.

What is the benefit of effective Thermal Mass?

The insulating properties of the foam panels and the thermal mass of the concrete core work together to create an energy-efficient building envelope. Because of this, heat pumps are ideally suited for an ICF dwelling built with PolyBloks.

The steel ties in our insulated concrete blocks are typically thin and spaced at intervals, allowing the majority of the wall’s cross-sectional area to be composed of concrete. This concrete core provides the effective thermal mass, helping regulate indoor temperatures and contributing to the energy efficiency of the building. Proper insulation and the use of concrete within the ICF system create a wall with excellent thermal properties, ensuring a comfortable indoor environment while minimizing heating and cooling costs.

Temperature Variation

When the external temperature drops or rises it can take 10-12 hours for the insulated concrete form walls to reach the same temperature without any energy input.

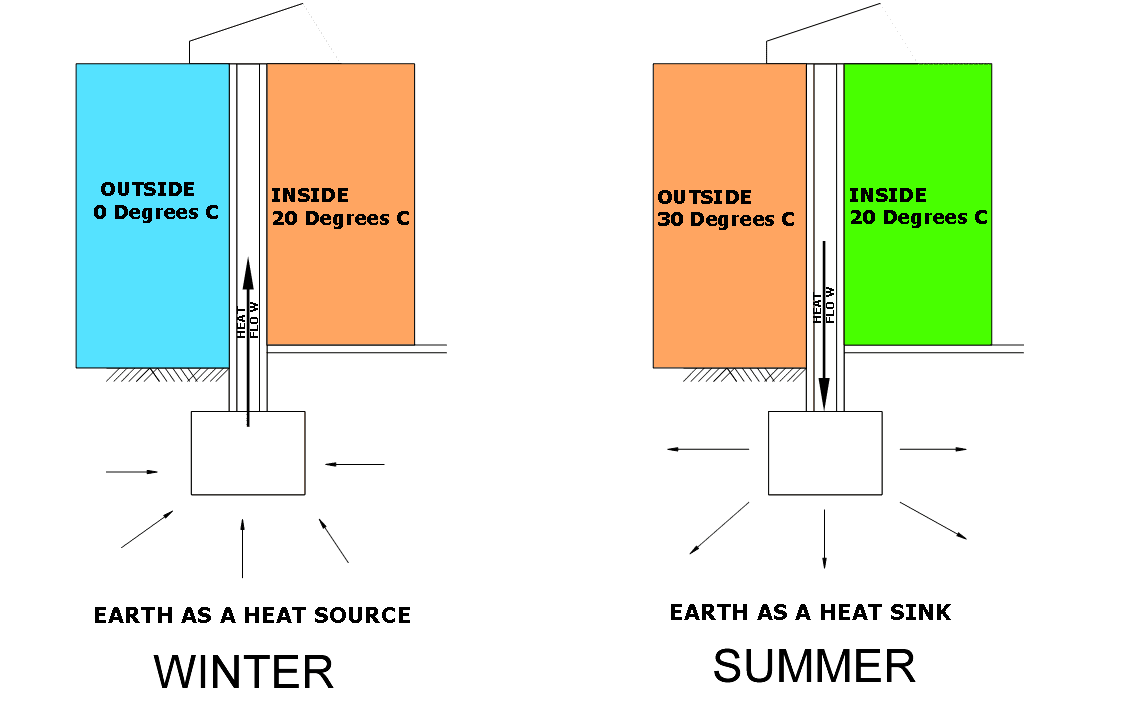

Summer / Winter

PolyBlok ICF walls are based on footings buried deep into the earth. This adds to the warming and cooling effects as the concrete is heated from below in winter but cooled in summer.

ICF Homes

Houses built in ICF Insulated Concrete Forms such as PolyBloks remain much warmer in winter and much cooler in summer. They cost a lot less to heat and do not need air-conditioning for summer.

Air Leakage.

Changes to the rules…

The June 2022 Building Regulations contain stringent new rules on Air Leakage. The notional dwelling permeability is set at 5m3 / hour / m2 at 50Pa.

Every new building will need to be tested after construction and then approved. Just imagine the hassle when a building fails.

ICF provides the best solution to building highly energy efficient homes which comply to these new standards.

Triple Air Barrier

An air barrier must be continuous to be effective and ICF provides this continuity. Indeed, ICF provides a triple air barrier: the concrete is continuous, has no joints and the two layers of rigid insulation also meet the requirements of an air barrier with the interlocking joints providing continuity.

Concrete as an air barrier

The air barrier needs to resist positive and negative pressures induced by wind, fan and internal / external pressure differentials. Flexible membranes must be supported on both sides or made of self-supporting materials such as board products fastened securely to the structure. Any tape or sealants must also resist these pressures and last the life of the building – something that is virtually impossible to achieve with any product that comes out of a tin or a tube.

Thermal Bridging.

Thermal bridges (or cold bridges) are weak points in the building which allow heat to escape. Stopping this is essential to increasing a building’s energy efficiency.

Thermal bridges in ICF walls can easily be eliminated if window and door openings are framed with timber, placed within the cavity between EPS leaves. This is not the case in cavity walls where there are 2.5 ties/m2.

The June 2022 Building Regulations require drawings to be provided for all junctions and complex details avoided where possible. Photographs will need to be taken to confirm that the design details have been constructed.

Polysteel can provide the Linear Thermal Transmittance figures required for the SAP calculations for the wall corners and wall floor junctions.