A growing phenomenon

ICF: A Global Market

ICF is taking off around the world thanks to the speed of construction, energy efficiency and design flexibility. It is used for residential and non-residential construction.

In the US over 35% of new dwellings are built with ICF – and use is growing rapidly at 5% per annum – especially in regions where hurricanes are frequent and the disaster resistant properties of ICF are so attractive.

Worldwide

$800M

Globally, the ICF market is growing exponentially and is currently worth $800million.

United Kingdom

About 4,000

It is understood that about 2% of the dwellings built in the UK are using ICF.

US Market

$200M

Leaders in ICF, the current US market is worth $200million and grows at about 5% per year.

Industrial Buildings

ICF is ideal for the construction of industrial or agricultural buildings but few if any are being built.

ICF: Revolutionising House Construction

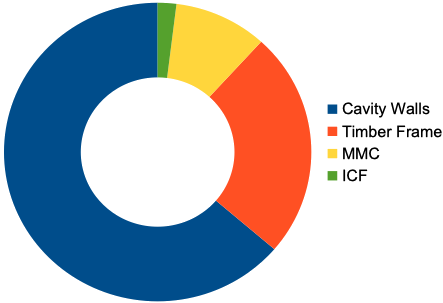

ICF, Timber Frame or Cavity Walls?

In the UK the use of Insulated Concrete Forms (ICF) construction is limited to self-builders and a few developers but this is likely to change rapidly in the near future are the building industry gets to understand the unique properties of ICF construction.

How much does it cost?

Increasing Labour Costs

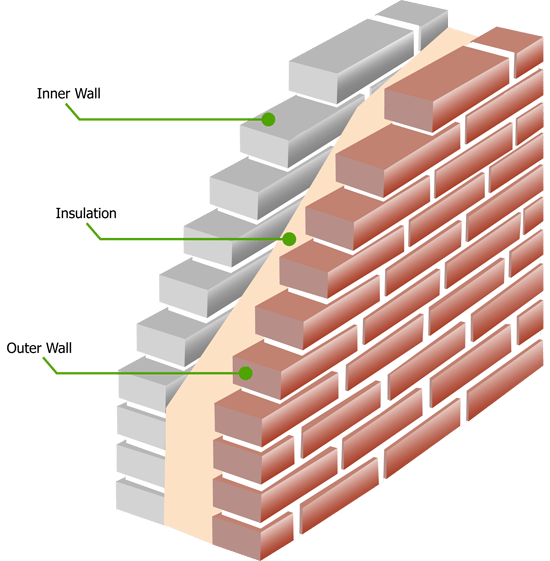

Builders who don’t move from traditional construction methods are likely to see labour costs increase exponentially. For instance, soon they will need to prove with photographs that the cavity walls comply with the Regulations – every Builder will be painfully aware of how much extra supervision this will require.

Reduced Workforce

To make matters even more difficult, the UK construction work force is reducing by 50,000 to 60,000 people per annum. And less than half of these are being replaced by apprentices.

A Cost Comparison

ICF

✓ £60 – £70 /m2 + cost of concrete + labour

✓ 10 days with semi-skilled labour to build up to eaves level

Timber Frame

✓ £80 – £100 /m2 + labour

✓ 2 weeks for a quote and over 10 weeks for delivery

Cavity Walls

✓ 50% of total cost is labour (£75+ /m2)

✓ 2 months to reach eaves level using skilled labour