How Thermal Mass reduces the Carbon Footprint

Understanding the sustainability of ICF.

Out of Touch Building Regulations.

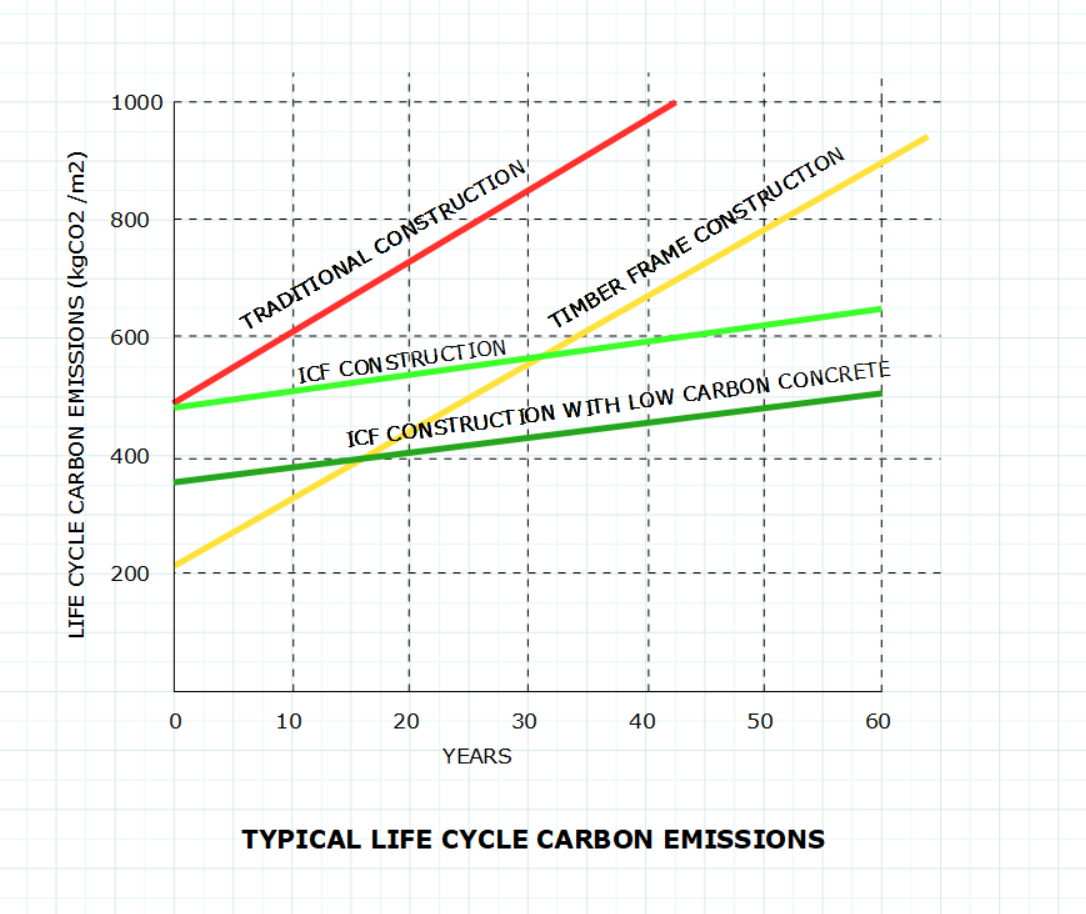

Cement manufacture generates a lot of carbon and because 15-20% of concrete is made of cement, ICF has a reputation of having high carbon footprint. Comparatively, the timber in a timber frame building is considered to have zero carbon footprint if a new tree is planted to replace the one that the timber came from. The insulating materials also have low carbon footprints. So the initial carbon footprint of Insulated Concrete Formwork is high compared with timber frame construction.

Governments are increasingly paying attention to the different types of emissions that buildings contribute to the atmosphere and the UK is doing the same by amendments to the Building Regulations.

Currently, UK regulations are all based on saving energy with no regard for the comfort of the building user and ignore the carbon footprint of the building materials. Any logical system that takes climate change into account would balance the carbon footprint of the construction materials against the fossil fuel energy use. We are very unlikely to see regulations based on this approach in the near future, if ever.

Building Life Cycle Analysis.

A life cycle analysis is a tool used to compare the carbon footprints of different building materials and construction methods. A study by the Rocky Mountain Institute found that ICF walls have a lower life cycle carbon footprint than timber frame walls in all climate zones.

The study found that ICF walls have a life cycle carbon footprint of 119 pounds of carbon dioxide equivalent per square foot of wall, while timber frame walls have a life cycle carbon footprint of 213 pounds of carbon dioxide equivalent per square foot of wall and that over a 30-year period, ICF walls can save homeowners an average of $72,000 on energy costs compared to timber frame walls.

In 2016 the ICFMA (Insulated Concrete Forms Manufacturers Association) in the US carried out a study into the Thermal Performance of an ICF wall system and 6” x 2” wood frame wall system that showed that the ICF wall would reduce energy use by 60%.

They found that the ICF energy savings are provided by the thermal mass of the concrete, the air tightness of the walls and the bridges in the insulation in the timber structure.

It is also clear that the energy savings over the building life will dwarf the initial negative carbon footprint of ICF walls as fossil fuels are going to be in use for a long time before they are eventually phased out.

Using Thermal Mass in Design.

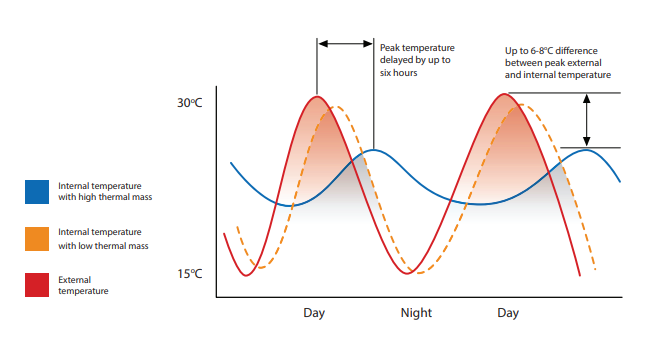

Thermal mass is a property of a material that describes its ability to store and release heat. This property could be used to great effect in housing design, as it can help to regulate indoor temperatures and reduce reliance on heating and cooling systems. The effect of thermal mass is not applied in a rational, coherent way in the UK Building Regulations and as a result the main advantage of ICF over timber frame construction is being ignored by the Government.

The graph illustrates just how much extra heating or cooling is required as it will be directly proportional to the difference between the blue and dotted orange lines.

It is also clear that air-tight super-insulated houses made from lightweight materials will suffer from overheating problems in the UK, especially if summer temperatures increase as forecast.

The Government is encouraging the construction of timber frame buildings because of climate change and yet these buildings are the ones that will be the most uncomfortable in the hotter summers that we are told are coming…

The only Modern Method of Construction that provides the Thermal Mass that is so necessary for comfort and reduction in energy cost is provided by Insulated Concrete Formwork and Polybloks provide a bigger Thermal Mass Effect than ICF forms with plastic ties.

Low Carbon Concrete.

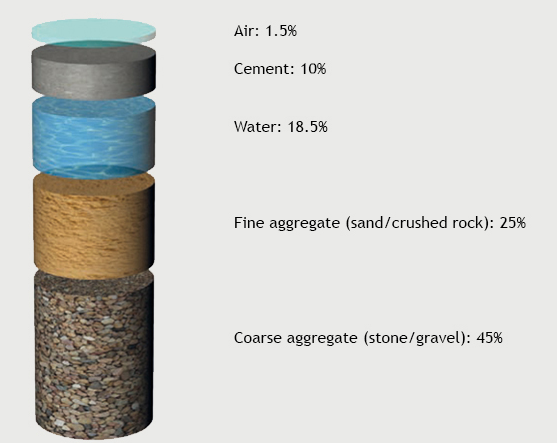

Low carbon concrete is a type of concrete that has a lower carbon footprint than traditional concrete. This is achieved by reducing the amount of cement used in the mix, or by using alternative materials that have a lower carbon footprint.

Cement is a major source of greenhouse gas emissions during the production of concrete. The manufacturing process of cement releases carbon dioxide into the atmosphere. This is because limestone is heated to a high temperature to produce lime, which is then combined with clay to make cement clinker. The clinker is then ground to a fine powder, which is added to water and aggregates to form concrete.

There are a number of ways to reduce the carbon footprint of concrete. One way is to use alternative materials to cement. These materials can include fly ash (a by-product of coal combustion), slag (a by-product of iron and steel production) or silica fume (a by-product of smelting). These materials can be used to replace some of the cement in the concrete without affecting it’s strength or durability.

Another way to reduce the carbon footprint of concrete is to use more efficient manufacturing processes. For example, cement kilns can be retrofitted with carbon capture and storage (CCS) technology. This technology can capture carbon dioxide before it is released into the atmosphere.

Low carbon concrete is a growing market. This is because there is increasing demand for sustainable building materials. Low carbon concrete can help to reduce the environmental impact of the construction industry.

If the developer/owner of the building wants to reduce the carbon footprint of their new building then low carbon concrete can be used and the building will still benefit from the thermal mass, air-tightness and sound insulation qualities of ICF.