Basement Construction Guide

Maximising Space with ICF Technology & Design

Building a Solid, Insulated, and Energy-Efficient Substructure.

If you are considering adding significant space and value to your property, a well-executed basement construction project may be the best solution. Unlike costly extensions or disruptive loft conversions, building downwards unlocks a new dimension of potential living space. But for a modern, dry, and energy-efficient subterranean level, the choice of construction material is everything.

At Polysteel, we specialise in Insulated Concrete Formwork (ICF), providing one of the only BBA Certified system in the UK specifically approved for basement walls. We believe that if you’re going to build a basement, you should build it once and build it right. This means choosing a system that delivers a high-quality, Grade 3 (habitable) space to BS8102.

Polysteel ICF will provide robust, fast, and thermally superior basement construction that sets the standard for quality.

Pros

Cons/Challenges

Beneficial Basement Uses.

With the rising cost of land and a demand for larger homes, a high-quality basement is no longer just a cold storage room. An ICF basement provides a dry, thermally-regulated, and soundproof environment perfect for premium living spaces.

New Build Basement Structure.

Where land is expensive, particularly near city centres, developers and builders are choosing to include basements in new construction projects. Adding a basement to a new build is often surprisingly inexpensive, especially when using ICF (Insulating Concrete Forms).

While the construction requires reinforced walls and a base slab, and disposal of excavation arisings is a primary cost factor (which can sometimes be offset by landscaping), waterproofing is usually easy and economical where groundwater is not an issue. Overall, the design is straightforward and the construction process carries very little risk in a New Build Project.

There are three basic methods of basement construction: ICF, Dense Concrete Blocks or Shuttered Concrete.

ICF (Insulated Concrete Formwork)

Not all ICF is suitable for Basement construction – But Polybloks by Polysteel are certified for basement use by the BBA

Pros

Cons/Challenges

Dense Concrete Blocks

This is a traditional, blockwork approach that involves the use of large very heavy hollow concrete blocks that are reinforced and filled with concrete.

Pros

Cons/Challenges

Shuttered Concrete

This method uses temporary timber or steel formwork into which concrete is poured.

Pros

Cons/Challenges

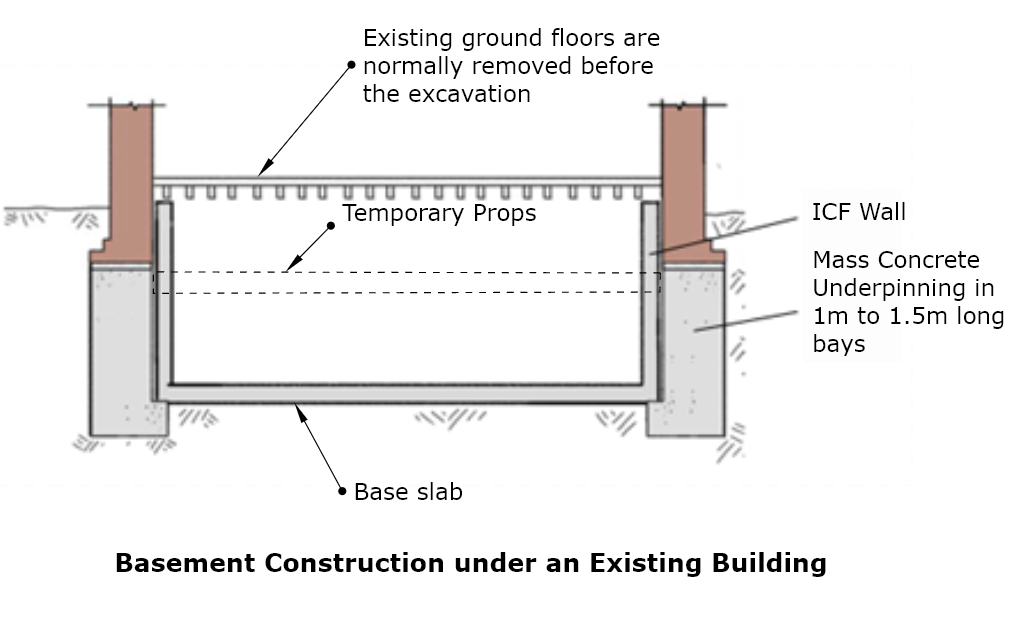

Basement Construction under Existing Properties.

These cost a lot more to build because of the limited space for access and the necessity to support the weight of the existing house. This is made even more difficult if the plot is narrow. In fact, this is likely to be the case, because if there is a large garden then there will be space around the house for extensions.

If the property is terraced or semi-detached the design will need to be incorporated into a Party Wall Agreement that will need to be negotiated with your neighbour(s) solicitors. A Structural Engineer will be needed by you and your neighbour and you will pay for both of them. This is always a time consuming and expensive process.

The mass concrete is placed in bays around the building perimeter, the basement is excavated with temporary props holding the walls and underpinning in place and the RC retaining walls are then built. ICF speeds up the process considerably, but the process is complex and a highly experienced Structural Engineer is essential.

Basic Principles

Final Thoughts.

Whether you are planning a Grade 3 habitable space for bedrooms, a soundproof home gym, or a high-spec swimming pool, the foundation of your success lies in the quality of your basement construction method. Traditional materials introduce risks like poor insulation and potential water ingress. Polysteel ICF PolyBloks eliminate these concerns by delivering a monolithic, heavily insulated, and virtually waterproof structure as standard. Basement construction is an investment in the permanent value and energy efficiency of your property.

Ready to start your basement construction project? Speak to a Polysteel engineer today to review your plans and assess the precise requirements of your build.