Building High Quality ICF Basements

When properly executed, ICF Construction creates a high-quality, energy-efficient, and durable basement space for residential and commercial buildings.

Polysteel is one of the only UK ICF manufacturers with a BBA Certificate approving the forms suitability for use in basement construction (Section 4.4.).

Furthermore, the concrete forms a bond with our steel ties which stops water transmission through a wall. The larger polypropylene webs used in many ICF forms do not stop water transmission, because concrete does not chemically adhere to PVC and their large irregular profiles provides a much longer perimeter for water to seep through.

Basement Construction: 4 Main Steps.

ICF forms are used for most types of structures, including basements with different uses. We will restrict our consideration of basements here to residential buildings.

Suitable basement construction is split into 4 main steps:

1. Identify Basement Use

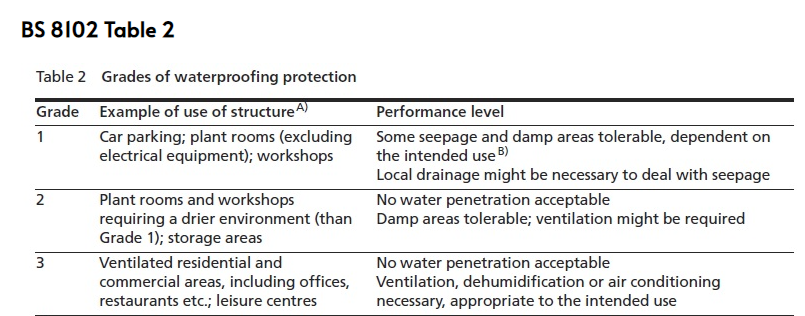

Table 2 from the British Standard BS8102 provides identification of the required use and the appropriate water proofing Grade.

2. Gather Site Information

This involves identification of all previous site activities and site testing of the sub-soil and ground water levels. Gas can be present in the form of methane, carbon dioxide or radon and may need to be identified by gas testing specialists.

3. Choose Construction Method

Basements are usually built with concrete walls of one form or another. Some engineers use brick or block walls with a concrete infill. However, these are time consuming and costly to build compared with ICF PolyBlok walls.

4. Select Waterproofing Type

The waterproofing can be bonded directly onto the ICF face or be in the form of a DPM type membrane hung down the wall from a horizontal fixing just above ground level. A land drain at the base of the wall will take the water deflected from the wall by the membrane to a sewer, ditch or soak away.

Basements In Residential Buildings.

In residential buildings there are two typical structural layouts. Most dwellings have basements when the house is on a hillside and the rear wall is to be a retaining wall. The ground can slope down on either one or both sides of the building so the at the front of the house, the floor level is at the same level as the ground outside. In these circumstances it is relatively easy to ensure that water ingress does not occur by installing a land drain around the three sides of building that are retaining soil.

The alternative type of basement is where there is a whole floor level below ground. This requires more detailed consideration of the groundwater levels in the soil around the basement and the use of the basement.

Building Basements with ICF.

ICF Polybloks are extremely useful and versatile in residential basement construction for the following reasons:

In virtually all soil types, DPM type membranes can be fixed to the outer wall and carried down the wall to enclose a perforated land drain at the foot of the wall. This can discharge into a soakaway, ditch or sewer on the slope below the house in most circumstances. However discharge into a sewer may require the consent of the local water authority.

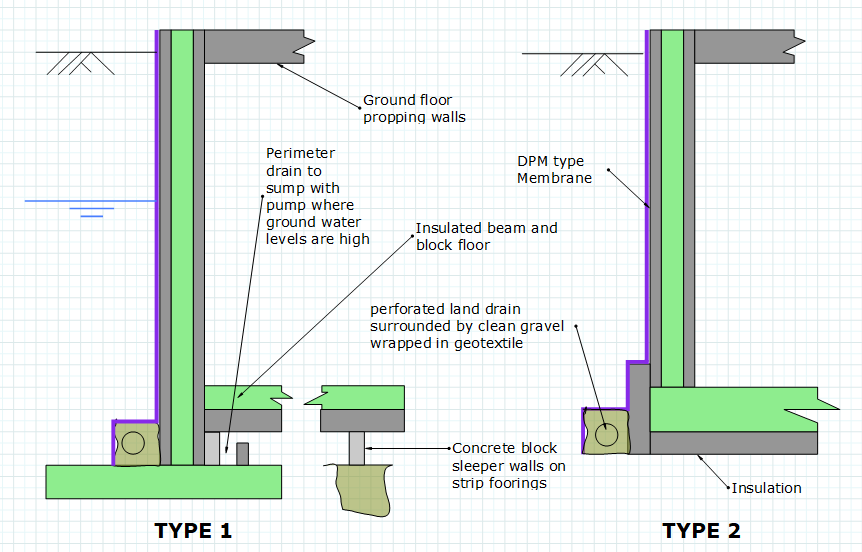

If the ground water levels get very high it is possible to have leakage between the foot of the ICF PolyBlok wall and the base slab. In this instance, an internal drain can be provided around the perimeter of the building which drains to a sump with a submersible pump beneath the finished floor level in the basement.

Basement Waterproofing Repairs.

Some websites inaccurately claim ICF is unsuitable for basement construction due to “a huge number of joints’’ or the inability to check the concrete after installation”. In fact, there is only one joint in an ICF wall located between the bottom of the wall and the base slab. The extremely high quality of concrete cured inside the EPS forms and the 3D grid of wires in ICF PolyBloks stop all shrinkage cracks. As a result, ICF basements built with PolyBloks are virtually waterproof without specialist waterproofing and are far superior to concrete walls built with formwork. However, it is essential to ensure the concrete pour is carefully controlled to ensure that the correct specification is used and the concrete is vibrated properly.

While leaks in icf basements might be difficult to repair, they will not leak if they are designed and built properly in the first place.

If there are any doubts about the likelihood of persistent high water levels, an internal drain should be installed (see Type 1 below).

Structural Options.

There are two primary structural arrangements incorporating the use of Polybloks in an ICF basement retaining wall:

Inverted T (Type 1):

Retaining walls are built with the toe of the wall about 400-500mm below the internal floor level. The floor is then formed in a conventional beam and block type floor. Supported by concrete block sleeper walls that are built on the toe of the retaining wall at one end and conventional footings at the other end. This is mostly used on hillside buildings where the front of the building does not need to be a retaining wall or where there is a risk of water penetration.

Reinforced Slab (Type 2):

The entire basement floor is covered by a reinforced concrete floor slab, 200-300mm deep, depending on the width of the basement. The ICF walls are installed around starter bars cast into the basement slab. Further reinforcement is installed over the entire wall so the retaining wall and basement slab act as one structural element.

Considerations.

Reinforcement that has a diameter greater than 12mm is very difficult to use in ICF. The horizontal steel bars must be specified in a way that suits the ICF course heights. Many Structural Engineers over provide the area of steel required because of their ultra-conservative approach to retaining wall design.

In most basements less than 3m high, vertical reinforcement should be no more than H10 bars at 150mm c/c if the wall is propped by the ground floor before backfilling around the basement walls.

Polysteel provides all the technical support, BBA certification, and quality manufacturing you need to confidently deliver high-performance icf basements that are structurally sound and highly energy efficient. Call us today to get started on your next icf basements project.